China M12X1.25 Banjo Bolt for Reliable Performance & Durability

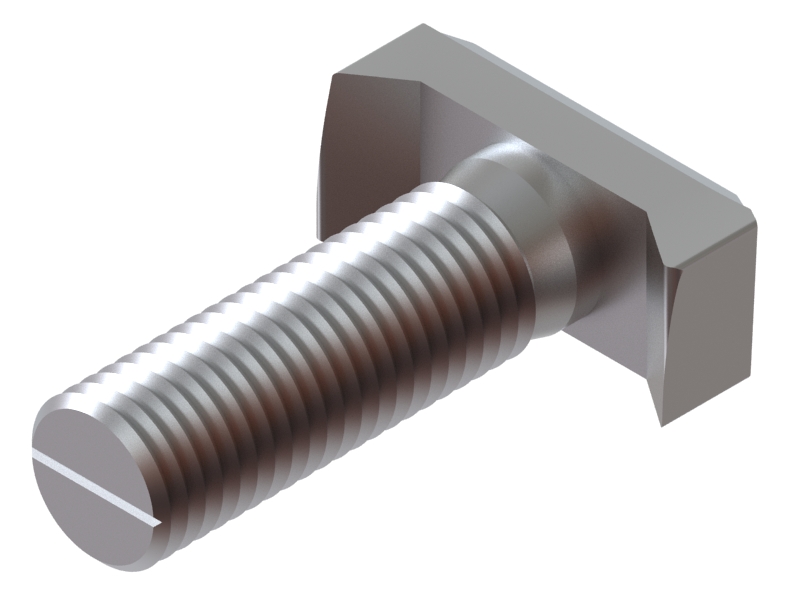

When I was sourcing components for our latest project, I realized how crucial the right parts are, especially when it comes to precision like the China M12X1.25 Banjo Bolt. This component is designed to meet exacting standards, ensuring reliable and secure connections in fluid systems. I often find that buyers seek durability and performance, and this banjo bolt delivers on both fronts. Important for applications that require a tight seal, its robust construction can withstand high pressures, making it a top choice for industrial machinery. As I was comparing options, the competitive pricing and availability really stood out. Plus, I appreciate that it’s easy to install, reducing assembly time and minimizing errors. For businesses focused on mechanical reliability, this banjo bolt is a smart investment. Don’t compromise on quality; ensure your projects run smoothly with dependable products like this that are backed by efficient supply chains.

China M12X1.25 Banjo Bolt Leads the Global Market Service Backed by Expertise

In the dynamic landscape of industrial components, the M12X1.25 banjo bolt stands out as a critical element in various applications from automotive to hydraulic systems. Its design facilitates efficient fluid transfer, making it an essential component for manufacturers seeking reliability and performance. With an increasing demand for high-quality fasteners globally, the M12X1.25 banjo bolt has emerged as a leader, helping businesses optimize their production capabilities and enhance their product offerings. The global market's preference for this specialized fastener stems from its robust construction and the expertise behind its production. Quality assurance and precision manufacturing processes ensure that each bolt meets rigorous standards. This enables businesses to minimize downtime, reduce maintenance costs, and improve overall operational efficiency. As industries evolve and technology advances, suppliers that prioritize these key factors will continue to thrive and meet the ever-changing needs of their clients. For procurement professionals, choosing the right supplier is vital. Opting for a manufacturer with extensive experience in the hardware sector can translate into significant advantages. Not only do they understand the intricacies of product specifications, but they also provide insights into trends, applications, and innovations in the fastener market. By aligning with knowledgeable partners, buyers can position themselves strategically, ensuring their products are equipped with components that reinforce durability and performance in their end applications.

China M12X1.25 Banjo Bolt Leads the Global Market Service Backed by Expertise

| Dimension | Material | Finish | Application | Market Demand |

|---|---|---|---|---|

| M12X1.25 | Stainless Steel | Polished | Automotive, Industrial | High |

| M12X1.25 | Carbon Steel | Zinc Plated | Mechanical Systems | Medium |

| M12X1.25 | Aluminum | Anodized | Aerospace | Growing |

| M12X1.25 | Titanium | Natural | Medical Equipment | Stable |

Related Products